Brick Inspection

Raise the efficiency of your production

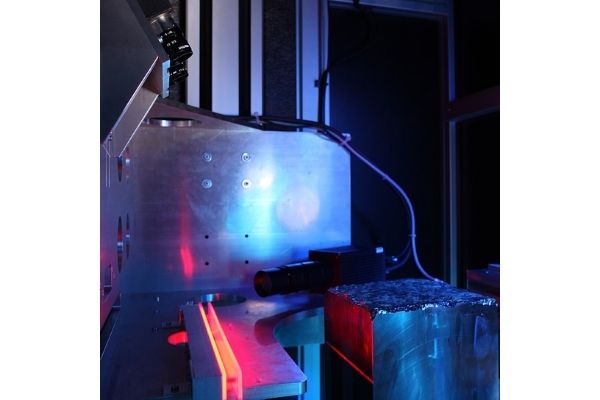

From the silicon raw material, crystal ingots are grown, which are sawn into the silicon blocks. It is reasonable to sort out faulty parts as soon as possible or, even better, to avoid processing them. Our ORION silicon block inspection systems offer a fully automated solution for inspection prior to the two process steps of polishing and wafer sawing:

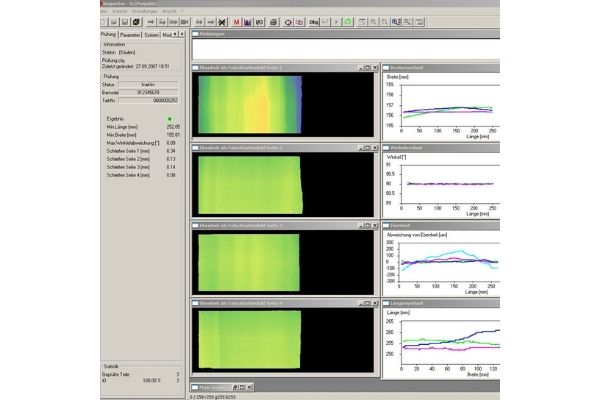

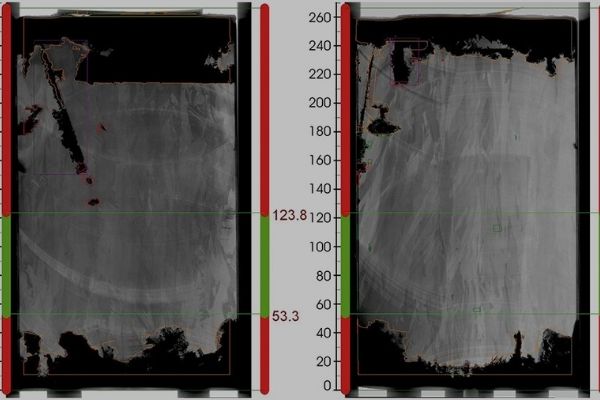

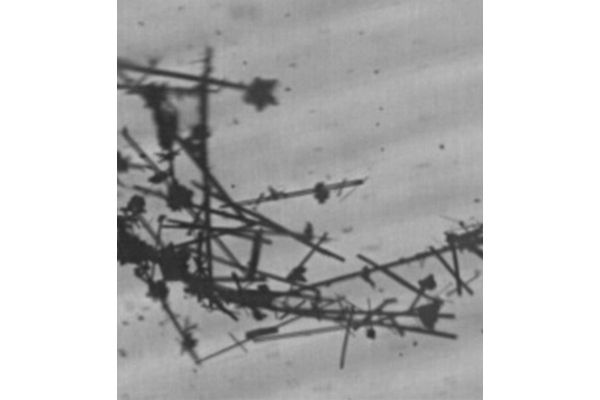

- The ORION NIR inspection generates cutting recommendations for the wafer sawing process. With knowledge of the inclusions in the material, a suitable process solution can be found.

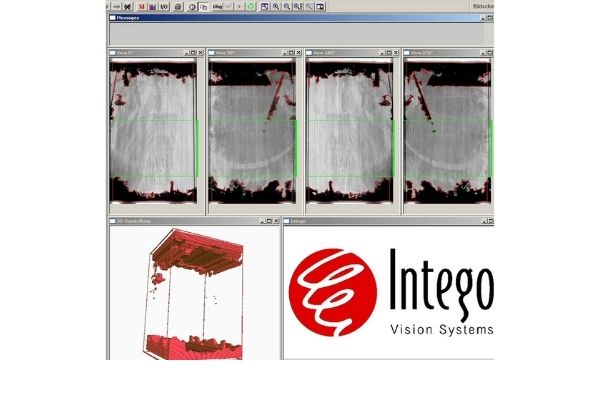

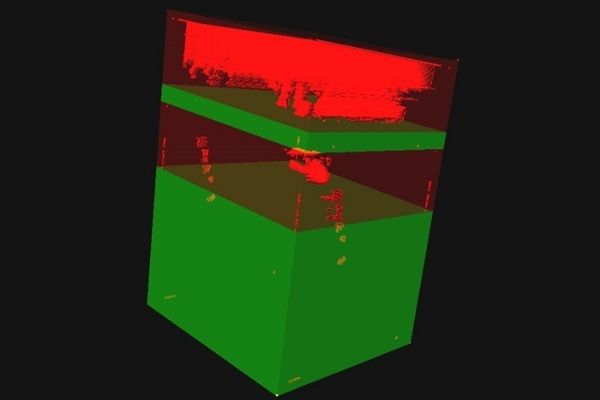

- The ORION 3D geometry measurement system generates recommendations for the polishing system to reduce the polishing effort.

The automatic inspection of silicon blocks is suitable for continuous automated production and for manual operation as a stand-alone system, e.g. for the laboratory. It is possible to combine the two systems into one machine.